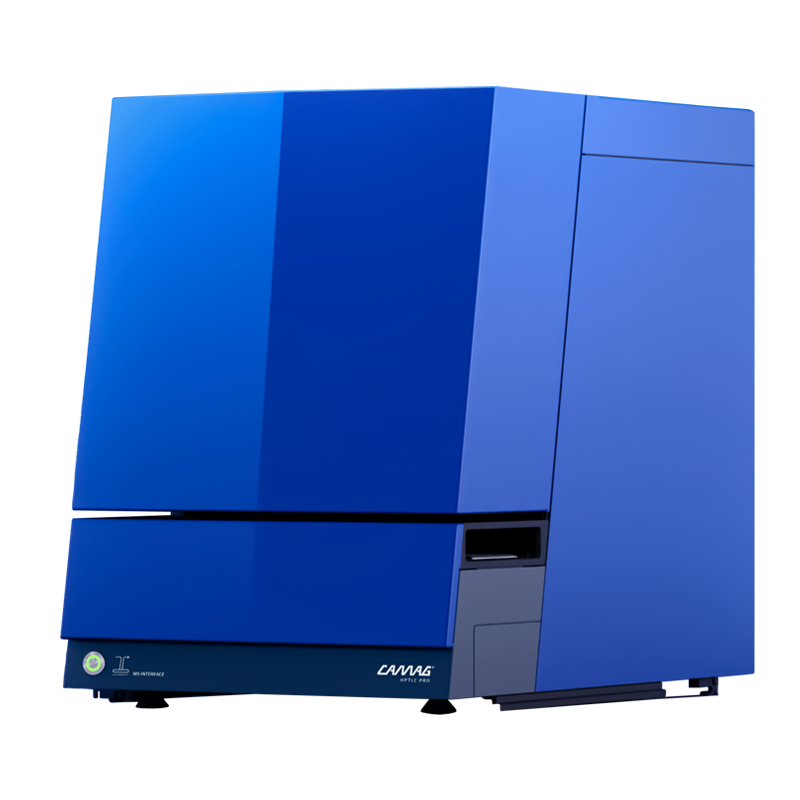

CAMAG®

HPTLC PRO

Fully automated analytical system for routine quality control

In a nutshell

First fully automated HPTLC system worldwide

The HPTLC PRO SYSTEM is a state-of-the-art analytical system engineered to transform laboratory workflows through full automation of the HPTLC process. It ensures precise qualitative and quantitative analyses across diverse industries, including pharmaceuticals, food safety, environmental testing, and herbal drug analysis. With Swiss-engineered precision, it meets advanced analytical demands with unparalleled reliability.

The system employs 20 x 10 cm HPTLC plates and features an innovative high-throughput design that automates each process step. Its modular setup processes up to five glass plates autonomously, even overnight, drastically improving efficiency.

Tailored for routine quality control of analytes from complex matrices, the HPTLC PRO SYSTEM delivers reproducible and reliable results. By eliminating manual intervention, its conveyor system seamlessly transports plates between modules, streamlining the workflow.

Compliant with cGMP standards, the HPTLC PRO SYSTEM ensures consistent results while reducing operating costs, thanks to its minimized solvent consumption.

-

Full process automation

-

No manual intervention

-

Analysis of up to 75 samples in one run

-

Built-in conveyor for plate transfer

-

Modular design

-

Software-controlled with visionCATS

CAMAG® HPTLC PRO

System mode

CAMAG® HPTLC PRO

System mode

Stand-alone operation

When operated as stand-alone, the HPTLC plate is inserted on the left side and ejected on the right side after processing.

HPTLC PRO Module APPLICATION

-

Autonomous application of up to 75 samples

-

Optimized spraying procedure adapted for each sample solvent

-

Software-controlled by visionCATS

HPTLC PRO Module DEVELOPMENT

-

Development of up to 5 HPTLC plates (20 x 10 cm)

-

Support of up to 3 different developing solvents

-

HPTLC glass plates (20 x 10 cm)

HPTLC PRO Module DERIVATIZATION

-

High-precision spraying of derivatization reagents

-

Integrated plate heating unit

-

Handling of two different derivatization reagents

HPTLC PRO Module DETECTION

-

Excitation with Xenon

-

Detection range from 200 – 830 nm

-

Absorbance and fluorescence measurement

HPTLC PRO Module MS-INTERFACE

-

Automated positioning of the elution head

-

Optimal cleaning procedure between elutions

-

Integrated elution pump

HPTLC Pro Module PLATE STORAGE

-

Prerequisite for autonomous processing of up to five HPTLC plates (20 x 10 cm) in the HPTLC PRO SYSTEM

-

Improved workflow and efficiency through one-time plate loading prior to analyses

-

Enables running a sequence of analyses autonomously overnight

CAMAG® HPTLC Software visionCATS

Related documents

Interested in the product?

Reach out to your local distributor and enjoy faster, improved results at reduced costs.